The History of Supply Chain Management

The history of logistics has a common thread running through it: our human desire to connect and communicate. From the ancient Silk Road to the modern, multi-tiered supply chain, this drive has led logistics to once unthinkable heights of innovation. Take just one look at the origins of the supply chain and the history of supply chain management and you’ll see why we are so excited about the future.

Communicate. Collaborate. Innovate.

The world of logistics can sometimes feel as complex as the Marvel multiverse. Today’s supply chains are globally interconnected networks of multiple relationships between buyers and suppliers, each with their own story and key role to play.

Given how far we’ve come as an industry, it’s worth pausing to look back at our own origin story. The history of supply chain management is not only fascinating, but it reminds us of an important constant in our industry: innovation. Consider it the superpower that has built the elaborate web of global, multi-tiered supply chains crisscrossing the planet today. As you trace your finger through supply chain history, you’ll also find some unexpected heroes: the humble inventions that brought radical change.

The history of supply chain management is a compelling tale that is far from over. Here's the story of how our industry has developed and what that tells us about where we are going next.

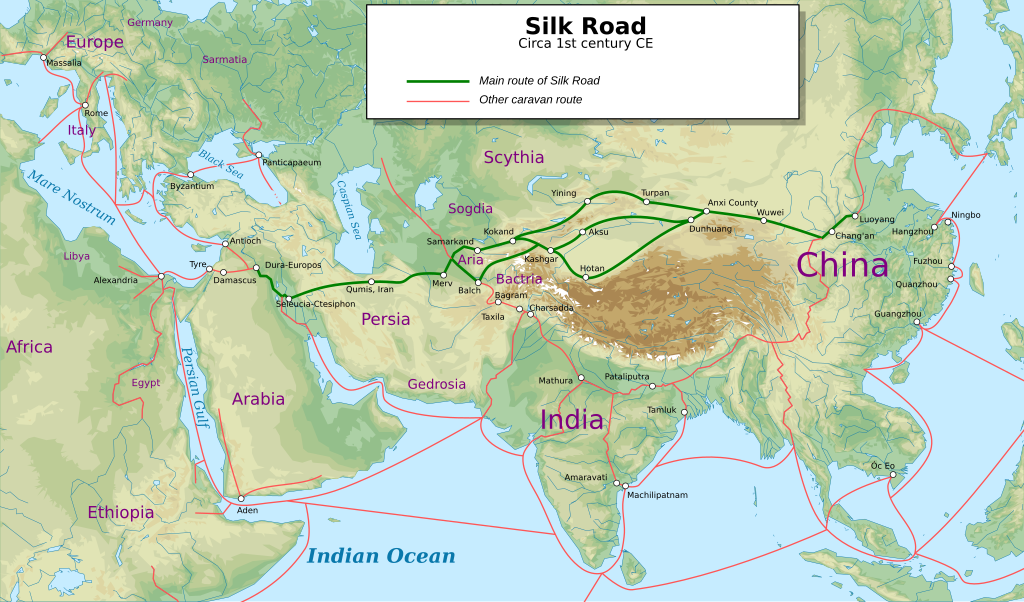

From China westward to the Mediterranean Sea

Author: Kaidor, This file is licensed under the Creative Commons Attribution-ShareAlike 4.0 International license.

Ancient routes – the early history of the supply chain

Today, we think of the term "hyperlocal” as a modern-day lifestyle trend. But in early agricultural societies it was simply a way of life. You gathered and grew what you needed, living off the land and utilizing what was right around you.

Or did you? In fact, trade and logistics have been around for centuries. And even in pre-industrial times, people were fascinated with the fundamental logistical challenge we face today: how best to connect goods and people in one place with goods and people in another. Admittedly, it was often war and conquest that led to the greatest strides in logistics transport and infrastructure, but the gains are undeniable. Goods have always been on the move, whether it be the famous mobility of the Roman legion, Alexander the Great’s depots and magazines, Persian royal roads, or the impressive logistical feats of the legendary Mongol cavalry.

Many versions of the supply chain origin story rush straight from the isolated farm to the advent of the railroad and US-European technological strides in the 19th century. But the complexities of Central Asian, Far Eastern, and African trade routes are proof that the logistical urge has always been present. Reaching out to share, explore, and communicate has been a common human pursuit. Medieval circumstances may have been hyperlocal, but traders still found innovative ways to move goods – and ideas – across continents. The Silk Road is probably the most well-known example of that. China’s modern Silk Road project is writing a new chapter in the history of this famous supply chain, opening up opportunities to expand trade routes and exploit the benefits of what was once the world’s main overland mode of transport: railroads.

Powering up – the origins of technology in transport

When trains first replaced horses for overland transport across wide expanses of the world’s surface, the pedestrian pace gave way to what at the time felt like lightning speed. The rapid expansion of the railroads in Europe and the United States in the second half of the 19th century made the transport of goods over great distances faster, easier, and less expensive.

At the turn of the 20th century, the all-new internal combustion engine revolutionized transport on the street after German automotive pioneer Gottlieb Daimler built the first motor truck in 1896. With the increased construction of paved roads, long-haul trucking soon became a reality. First gasoline powered, sometime later diesel and then electric before turning back to gasoline, heavy-duty trucks have been the pack animal of choice for much of the last 100 years.

In addition to trains and trucks, the industrial revolution saw steamships and telegraph technology dramatically change communication and travel. In a way, this was the magic moment when communication could outpace transportation: a message about a shipment or an occurrence could be relayed ahead of the arrival of a physical vehicle. Every good supply chain professional will recognize that as a pivotal moment in the history of supply chain management – one of those giant leaps forward.

Our origin story

Just months after man's first landing on the Moon, we began operating the first international door-to-door express delivery service in the world.

Humble Heroes – new logistics inventions radically change supply chain history

Superheroes usually have a trusty sidekick to help move the plot forward. In logistics, there are a few nominees for our best supporting actor that have transformed the industry. The pallet is most definitely one of them. This simple wooden construction, which evolved from skids that date back to Ancient Egypt, truly revolutionized the storage and movement of goods. In more recent history, World War II drove the colossal demand for usage pallets. Since then, except for a material tweak here and there for hygiene and durability, pallets have essentially remained unchanged since their invention.

But if you think pallets played an Oscar-worthy supporting role in the history of supply chains, then it’s time you met the container. The modern shipping container reshaped the transportation industry to such a great extent that it’s become the stock image of global cargo transport.

Before containers arrived on the scene, break bulk cargo required intense handling at every transfer point, which of course increased the potential for holdups and delays. Shipping containers of various sizes existed even in horse-drawn or steam-powered days, but it was the first standardized container patented in the USA in 1956 that brought about radical change. This ingeniously simple yet strong, reliable, and secure innovation single-handedly transformed cargo handling, port architecture, vehicle design, and supply chain planning worldwide. “Intermodal” containers that can be easily transferred between various modes of transport (e.g., trucks, trains, and ships) may truly be the ultimate sidekick in our supply chain superhero origin story.

Computerizing the supply chain – new technologies take logistics to a new level

As the physical side of the supply chain became more advanced and efficient, a host of new technologies came online in the second half of the 19th century that would greatly improve our ability to keep track of shipments and communicate around them. The bar code, invented in 1948, was scanned for the first time on a pack of Wrigley’s chewing gum in 1974. This moment ushered in a new era of warehouse monitoring, lean production models and, ultimately, just-in-time delivery and production practices.

Our story shifts into high gear from here as more manual processes begin to be automated and globalized goods become traceable and communicable. The growth of personal computing in the 1980s and the emergence of the internet in the 1990s opened the door to spreadsheet technology, map-based interfaces, and large-scale optimization models. This is also the time when the term “supply chain management” entered the scene – when the supply chain was no longer seen as a series of separate services and processes but as a single entity that could be centrally coordinated.

The advent of Enterprise Resource Planning (ERP) systems was a key enabler that allowed companies to integrate large amounts of data from separate data sources. Efficiency and accuracy – not to mention materials and logistics planning – took a giant leap forward. Add UPC barcodes and other kinds of ID tagging and suddenly the logistics industry could tag and track anything that moved. Automated warehousing and inventory management was having its moment in the spotlight. Now we could quantify and verify the movements of goods in a format that was sharable and ready to inform business processes across the entire supply chain.

SmartSensor – another hero of supply chain management.

The arrival of digital – supply chains take to the cloud

The parchment lists of medieval times may have been indecipherable to the common eye, but the digital coding needed in today’s supply chain management systems is literally illegible to the human eye. It’s nearly impossible even to keep up with all the acronyms in our business, like UPC, QR, EDI, CPS and RFID, to name but a few. More superhero sidekicks in the service of society.

In the most recent chapter in supply chain history, digital technology is rewriting the story yet again. Electronic data interchange (EDI) enables quick exchange of transaction details that has propelled the industry and the possibilities forward, much as telegraph and telephone technology did in their day. And cyber-physical systems (CPS) connect IT with logistics, traverse complexity with ease, granting supplier and customer alike eyes on the goods throughout. Radio Frequency Identification (RFID) technology allows supply chain companies to track and optimize workflows, inventory, assets, and processes. Smart sensors protect against changes in temperature, humidity, shock, light, and even air pressure – and they are providing the building blocks to a new Internet of Things (IoT) in logistics.

Supply chain professionals may not be able to bend the natural laws of the universe, but real-time visibility of information around goods and shipments is a stunning advance. The digital supply chain is here. Forward-looking companies are building intelligent, interconnected, and international networks – supply chain management systems that work in real-time, act proactively, and adapt dynamically. Collecting and managing all the information needed to run a digital supply chain requires a scalable data lake and linking everyone to it. That means turning to the cloud for connectivity, processing power, and data exchange.

These hyper speed developments can seem intimidating, much like the arrival of a steam locomotive in the 1800s. But industry leaders are recognizing that this moment in supply chain history is an opportunity to leverage real-time data insights for greater environmental and social responsibility. And they are utilizing the power of digital technology to facilitate communication and enable customized, local-to-local collaboration across vast, global supply chain networks.

How can AI improve supply chain performance?

AI – the next installment in supply chain history

In much the way a new, previously unknown spice would have boggled the medieval mind or the steam locomotive would have seemed lightning fast to the children of the industrial revolution, Artificial Intelligence (AI) in supply chain management is a modern wonder making an enormous impact. With AI, we’re already seeing leaner, swifter, and exponentially more complex processes than many in the industry could have envisioned. Machine learning-enabled or ‘smart’ systems are no longer a vision of the future but play a key role in today’s reality. Digital supply chains that predict and prescribe will become necessary to manage logistics in a more connected, complex, and disruption-prone world. The use of AI to predict equipment failures alone could save companies – and, in turn, consumers – millions, if not billions.

Collaborative robots for a better performance

Supply chain history – to be continued…

Supply chain management done well is largely invisible. The huge life-enhancing advances made as a result of the industry’s commitment to innovation are often only recognizable in the rear-view mirror. Relatively humble inventions have had world-reshaping impacts on the history of the supply chain. The industry has come a long way since horses and hand carts, but our need to communicate and exchange goods continues to drive innovation today.

If the history of supply chain management is any indication, we have not seen the last logistics hero – or sidekick for that matter. And if you follow the trends in logistics you’ll see that the next historic innovations are already on the radar.

Published: August 2022